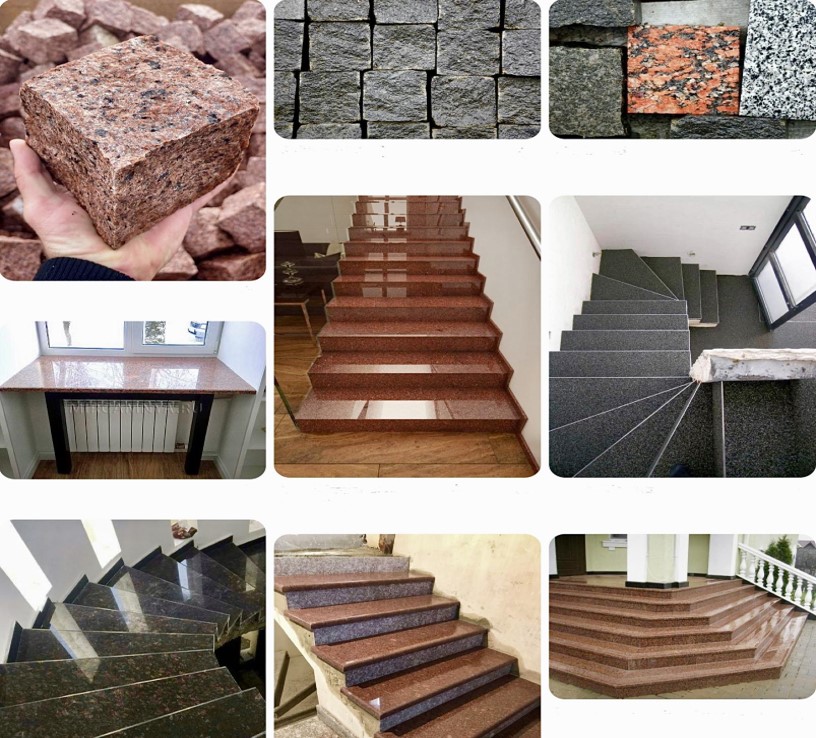

The sanded finish is even, but a little rough. Traces of abrasive tools are visible after it. This is a tougher degree of processing compared to polishing and buffing.

Sawn – a smooth, but slightly rough surface of natural stone with traces of processing with an abrasive tool. It is the natural surface of the stone after sawing with a diamond tool – disc diamond saws or diamond wire.

A heat-treated rough surface of natural stone, on which traces of flaking from the effect of a high-temperature plasma jet (gas burner) are visible, with a well-defined relief structure of the stone.

Cracked surface – results from the splitting of large pieces of natural stone into products, parts. Punched processing is considered the roughest degree of processing.